RoundScaff – Aircraft Nose & Fuselage Maintenance Platform

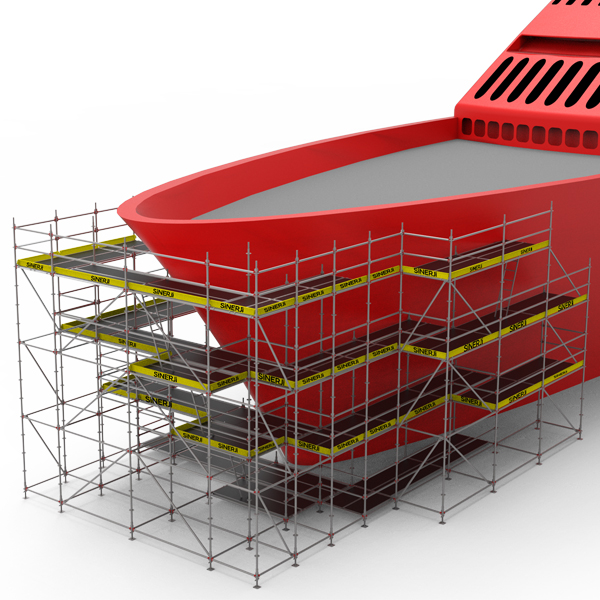

RoundScaff Aircraft Maintenance Platform is a modular aluminum scaffolding system designed to provide safe access to the aircraft nose, fuselage, and cockpit areas. Thanks to its flanged connection technology, it perfectly follows the contour of the aircraft body and creates an ergonomic, safe, and high load-capacity working environment for maintenance teams.

Product Features

Safety and precision are paramount in aircraft maintenance operations. For this reason, RoundScaff is engineered to deliver maximum compatibility and accuracy around aircraft nose and fuselage maintenance platforms.

Its flanged node connections allow scaffold elements to align with geometries that precisely follow the aircraft structure. This ensures safe access to both the cockpit and fuselage surfaces without making physical contact.

Aluminum platform surfaces offer wide working areas, while stair-integrated modules provide safe transitions between upper and lower levels. Non-slip surfaces, guardrails, toe boards, and diagonal bracing components ensure full compliance with international safety standards.

RoundScaff Aircraft Platforms are ideal for fuselage inspections, window replacement, panel removal and installation, sensor and antenna maintenance, and cockpit-area refurbishment operations in maintenance hangars.

Advantages

-

Flanged scaffold structure fully compatible with aircraft nose geometry

-

Safe working distance without touching the aircraft fuselage

-

Wide platform surfaces providing ergonomic working conditions

-

Non-slip surfaces and complete safety barrier system

-

Fast assembly and repositioning thanks to lightweight aluminum construction

-

Stair-integrated platforms for vertical access

-

Precise positioning even in confined hangar spaces

-

Smooth operation within maintenance hangar environments

-

Full compatibility with commercial aviation, military aircraft, and corporate jet maintenance programs

Areas of Use

-

Aircraft nose maintenance platforms

-

Fuselage surface inspection and panel replacement

-

Cockpit area maintenance, cabling, and sensor work

-

Windshield replacement and sealing inspection

-

Antenna, radar, and nose-section electronic equipment maintenance

-

General hangar maintenance scaffolds

-

APU and upper fuselage inspection areas

-

Maintenance platforms for military aircraft, passenger aircraft, and private jets

| Component | Product Description | Aircraft Maintenance Usage |

| Vertical Standards (50–300 cm) |

Vertical load-bearing column elements | Forms the main scaffold structure shaped to fit the aircraft nose contour. |

| Horizontal Ledgers (Ledger) (73–307 cm) |

Horizontal platform-supporting elements | Creates platform levels and working decks around the fuselage. |

| Reinforced Ledgers | Strengthened horizontals with increased load capacity | Used to form wide platform spans in general maintenance zones. |

| Diagonal Braces | Diagonal connections providing lateral stability | Ensures rigidity and reduces vibration on inclined fuselage areas. |

| Aluminum Platforms (30–60 cm width) |

Lightweight platforms with anti-slip surface | Provides a wide, safe walking surface around the fuselage. |

| Ladder Platforms | Vertical access module | Ensures safe movement between upper and lower platforms. |

| Guardrails (Inner / Outer) | Safety barrier components | Provides personnel safety at elevated working heights. |

| Toe Board | Edge safety element | Prevents tools or materials from falling off the platform. |

| Base Jack / Adjustable Base | Adjustable base component for ground load distribution | Ensures proper scaffold leveling on hangar floors. |

| Wall Tie | Structural anchoring component | Improves scaffold stability near the fuselage. |

| Ground Anchor Screw (Multi-Monti) | Ground fastening component securing the system | Provides base anchoring for safe scaffold installation. |