RoundScaff Flanged Scaffold – Tank & Silo Solutions

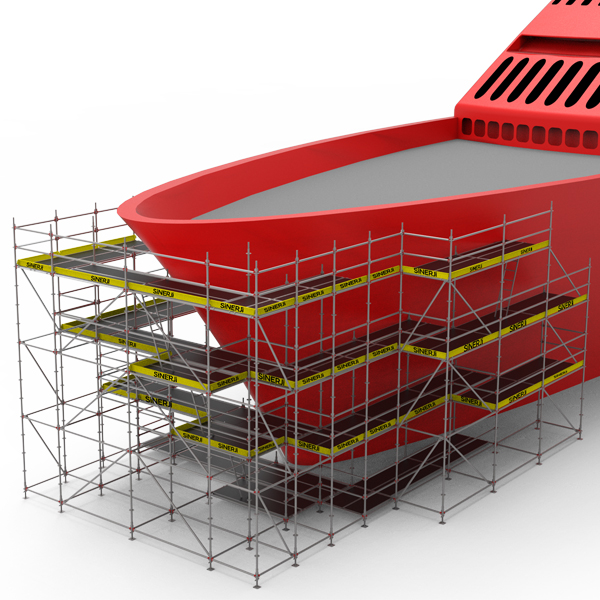

RoundScaff Flanged Scaffold – Tank & Silo Solutions is a modular aluminum scaffolding system designed to create safe, circular, and continuous working areas around tanks, silos, and all cylindrical structures. With its flanged node connections, it forms a perfectly circular geometry and ensures high stability.

Product Features

RoundScaff’s flanged connection technology provides 8-directional connection capability, allowing scaffold components to fit seamlessly around circular structures. This feature enables fast, safe, and precise scaffold installation around tanks, silos, and all wall-sided industrial storage units.

The high-rigidity horizontal–vertical grid system provides a safe working platform across large surfaces. The long-lasting aluminum body minimizes corrosion risk and enables safe use in chemical facilities. Toeboards, guardrails, ladder platforms, and diagonal braces provide maximum safety at all working levels.

RoundScaff Flanged Solutions are widely used in petrochemical plants, silo and tank production-maintenance areas, water reservoirs, filtration units, chimneys, and tower structures.

Advantages

-

Flanged node technology offering perfect compatibility with circular geometries

-

Ability to form 360° continuous platforms around tanks and silos

-

Fast and safe assembly thanks to its lightweight aluminum structure

-

Corrosion-resistant system suitable for chemical and petrochemical facilities

-

Modular design that follows curved and inclined surface geometries

-

Safe inter-level access with stair-integrated modules

-

High stability provided by diagonal bracing connections

-

Long service life with low maintenance cost

Areas of Use

-

Petrochemical facilities

-

Refinery storage tanks

-

Silo structures and storage units

-

Water reservoirs and filtration towers

-

Industrial chimney structures

-

Circular water towers

-

Maintenance, repair, insulation, and painting operations for storage tanks

| Component | Product Description | Tank & Silo Solutions Usage |

| Vertical Standards (50–300 cm) |

Vertical load-bearing column elements | Forms the main circular load-bearing structure around the tank. |

| Horizontal Ledgers (Ledger) (73–307 cm) |

Horizontal grid and platform-supporting elements | Enables the creation of 360° working levels around the tank. |

| Reinforced Ledgers | Strengthened horizontal members that increase load capacity | Used at points requiring wider spans along the tank perimeter. |

| Diagonal Braces | Diagonal connections that provide rigidity to the system | Provides additional stability around cylindrical structures. |

| Aluminum Platforms (30 / 60 cm) |

Main platforms forming the working surface | Ensures a safe and continuous platform surface around the tank. |

| Ladder Platforms | Platform type providing vertical access | Allows access to different levels around or on top of the tank. |

| Guardrails (Inner / Outer) | Upper-level safety barrier components | Ensures personnel safety on all working levels. |

| Toe Board | Edge protection element | Prevents materials from falling off the platform. |

| Base Jack / Adjustable Base | Adjustable base element that distributes load at ground level | Correctly positions the scaffold on sloped or uneven surfaces. |

| Wall Tie | Rigid connection element tied to the structure | Anchors the scaffold to the tank shell to prevent tipping at height. |

| Ground Anchor Screw (Multi-Monti) | Ground fastening component used to secure the system | Provides base anchoring for safe installation around the tank. |