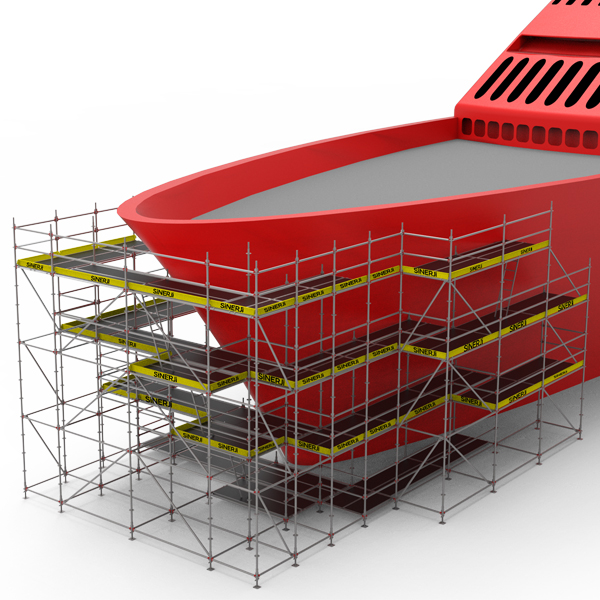

RoundScaff Ironworker Access Scaffold

RoundScaff Ironworker Access Scaffold is a safe, modular, and lightweight scaffolding solution developed for steel construction fabrication and installation processes. Its high-rigidity connection geometry, wide working platforms, and aluminum body structure enable fast assembly and a secure working environment both in factory production areas and on-site installation points.

With its high load-bearing capacity, easy portability, and short assembly time, it is an ideal mobile platform solution for ironworkers and steel fabrication teams.

Product Features

Key Features

-

Fast and safe assembly with a modular aluminum scaffolding structure

-

Comfortable working area thanks to wide platform surfaces

-

High rigidity and maximum stability with diagonal bracing connections

-

Quick assembly and dismantling enabled by lightweight structural components

-

Orientation compatibility with industrial areas and factory production lines

-

Enhanced safety with horizontal and vertical safety barriers

-

Scalable structure adaptable to different height requirements

-

Long-lasting corrosion resistance

Main Advantages

-

Provides a safe working platform for steel fabrication and installation operations

-

Reduces labor costs due to its lightweight structure

-

High load-bearing capacity suitable for heavy steel components

-

Modular architecture allows use even in narrow or confined areas

-

Non-slip platform surfaces ensure safe working conditions

-

Can be quickly adapted for multi-level working arrangements

-

Enables practical repositioning within production facilities

Areas of Use

-

Steel construction fabrication workshops

-

In-factory steel assembly zones

-

Industrial facility maintenance & installation operations

-

Manhole, steel pipe, and steel profile work areas

-

Steel frame and structural assembly platforms

-

Metal surface maintenance and sandblasting zones

-

Auxiliary working platforms in heavy metal processing lines

| Component | Product Description | Ironworker Solutions Usage |

| Vertical Standards (50–300 cm) |

Vertical load-bearing column elements | Forms the main supporting skeleton of the scaffold. |

| Horizontal Ledgers (Ledger) (73–307 cm) |

Horizontal load-bearing elements forming the deck level | Defines platform levels and the framework of the working area. |

| Reinforced Ledgers | Strengthened horizontal elements providing additional load capacity | Increases load-bearing capability for heavy steel components. |

| Diagonal Braces | Diagonal connections that provide rigidity to the system | Ensures stability and reduces vibration in steel fabrication zones. |

| Aluminum Platforms (30 cm / 60 cm) |

Platform elements forming the working surface | Creates a non-slip and safe surface in areas handling heavy materials. |

| Toe Board | Edge protection element | Prevents metal pieces from falling off the platform. |

| Guardrails (Inner / Outer) | Upper-level safety barriers | Ensures user safety throughout the working area. |

| Ladder Platforms | Platform type providing vertical access | Allows safe transitions in multi-level working arrangements. |

| Base Jack / Adjustable Base | Adjustable base component that distributes ground load | Ensures proper scaffold leveling on uneven floors. |

| Ground Anchor Screw (Multi-Monti) | Ground fastening component for securing the system | Provides maximum stability in heavy industrial environments. |

| Wall Tie | Rigid connection element attaching the scaffold to the structure | Anchors the scaffold to the structure for added safety. |