RoundScaff Shipyard Solutions

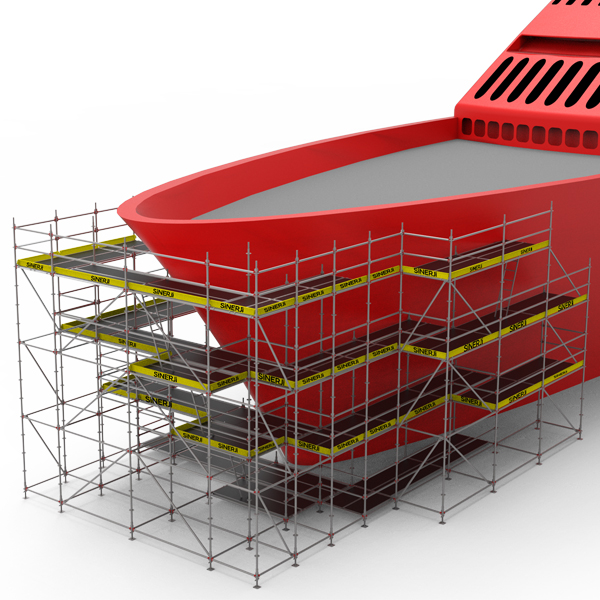

RoundScaff Shipyard Solutions is a modular aluminum flange scaffolding system designed to create safe, fast, and shape-following working platforms around ship hulls and stern areas. With its lightweight structure, high durability, and perfect compatibility with circular geometries, it delivers excellent performance in shipyard maintenance, repair, painting, and outfitting operations.

Product Features

The flanged connection nodes and modular aluminum components of RoundScaff allow the system to adapt perfectly to the complex and curved surfaces of a ship’s hull. The system can be shaped to provide continuous and safe access along sloped bow structures, hull sides, stern areas, side tanks, and dry-dock environments.

In shipyard operations, the most critical requirements are safety and platform stability. RoundScaff meets international safety standards with horizontal working decks, stair-integrated platform transitions, toeboards, and guardrail structures. In addition, its lightweight aluminum body significantly reduces scaffolding assembly and dismantling times.

Thanks to its modular configuration, the same system components can be reused across different vessel types, offering both economic and operational advantages for shipyards.

RoundScaff Shipyard Solutions is suitable for maintenance operations on all vessel types, including tankers, tugboats, coasters, cargo vessels, ferries, and military ships.

Key Advantages

-

Flanged scaffold geometry that fully adapts to ship contours

-

Ability to safely wrap hull, bow, and stern areas

-

Fast installation and easy handling due to its lightweight aluminum structure

-

Ideal platforms for painting, sandblasting, outfitting, and maintenance operations

-

Safe multi-level access with stair-integrated transitions

-

Corrosion-resistant and long-lasting aluminum components

-

Low maintenance cost with high reusability

-

Compliance with international safety standards (TSE, TÜV)

-

Full stability during dry-docking and floating dock operations

Areas of Use

-

Ship hull wrapping scaffolds

-

Bow and stern access scaffolds

-

Dry-dock maintenance platforms

-

Funnel and superstructure maintenance areas

-

Internal access for side tank operations

-

Outfitting and assembly platforms

-

Sandblasting and painting access structures

| Component | Product Description | Shipyard Use |

| Vertical Standards (50–300 cm) |

Vertical load-bearing elements with flanged connection nodes. | Forms the main scaffold support structure along the ship hull. |

| Horizontal Ledgers 73–307 cm |

Horizontal load-bearing members of working levels. | Used to align platform levels along the hull. |

| Reinforced Ledgers | Horizontal elements providing extra support for wider spans. | Enhances platform rigidity in bow areas or wide access zones. |

| Diagonal Braces | Diagonal members that provide lateral rigidity to the scaffold. | Ensures stability against wind loads and hull inclinations. |

| Aluminum Platforms (30 cm and 60 cm) |

Lightweight platforms forming the working surface. | Used as horizontal working decks along hull and bow sections. |

| Ladder Platforms | Platforms providing safe vertical access between levels. | Used for vertical circulation on large hull scaffolds. |

| Console Brackets | Components that extend scaffold lines outward. | Used for platform extension on inclined hull surfaces. |

| Toe Boards | Edge barriers preventing tools or materials from falling. | Enhances safety during painting and sandblasting operations. |

| Guardrails (Inner / Outer) | Protection elements used for personnel safety on upper levels. | Mandatory safety barriers at all working platforms. |

| Stair Guardrails | Side safety components of stair modules. | Used along vertical access routes. |

| Base Jack / Adjustable Base | Adjustable base element distributing loads at ground level. | Used at scaffold starting points in dry docks and dock floors. |

| Ground Anchor Screw | Ground fastening component for securing the scaffold. | Used in strong wind, inclined surfaces, and dock-floor anchoring. |

| Clamps (Fixed / Swivel / Plate) | Steel connectors used to fix tubes or special joints. | Used especially in tube bracing and custom corner solutions. |

| Wall Tie | Element used to anchor scaffold to the ship surface or safe point. | Prevents tipping on high hull sections. |

| Aluminum Ladders | Lightweight ladder modules for vertical access. | Provides vertical connectivity across all hull levels. |